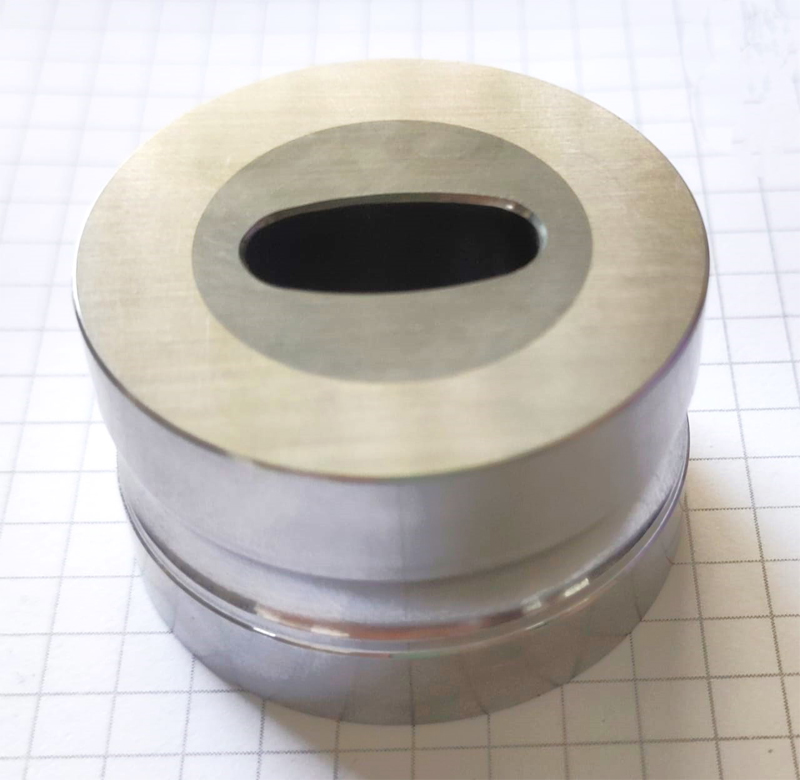

Carbide Inserted Dies for Tablet Compression Tooling

Our carbide inserted dies represent the pinnacle of precision and performance in tablet compression tooling, specifically designed to meet the rigorous demands of the pharmaceutical sector. Crafted with the highest quality materials and engineering expertise, our carbide inserted dies ensure unparalleled efficiency and durability in tablet manufacturing processes.

Features:

- Premium Carbide Inserts: Each die is meticulously crafted with premium carbide inserts, renowned for their exceptional hardness, wear resistance, and longevity. This ensures consistent tablet quality and prolonged tool life, minimizing downtime and production costs.

- Precision Engineering: Our dies undergo rigorous machining processes to achieve precise dimensions and geometric accuracy. This precision ensures uniform tablet weight, thickness, and hardness, meeting the strictest pharmaceutical standards with every compression cycle.

- Customized Designs: We offer a range of customized designs and configurations to suit various tablet shapes, sizes, and formulations. Whether it's round, oval, or special-shaped tablets, our carbide inserted dies can be tailored to meet your specific requirements with precision and reliability.

Benefits:

- Enhanced Productivity: With superior wear resistance and minimized tooling maintenance, our carbide inserted dies maximize productivity by ensuring consistent tablet quality and prolonged tool life. This translates to increased uptime and higher throughput in tablet manufacturing operations.

- Cost Efficiency: By reducing the frequency of die replacements and minimizing tablet defects, our carbide inserted dies deliver significant cost savings over the long term. Their exceptional durability and reliability help optimize operational expenses and improve overall production efficiency.

- Quality Assurance: The precision-engineered design and advanced carbide processing technologies incorporated into our dies guarantee superior tablet quality and uniformity, providing pharmaceutical manufacturers with the assurance of compliance with regulatory standards and customer expectations.

- Versatility and Adaptability: Our carbide inserted dies offer unparalleled versatility and adaptability to accommodate a wide range of tablet formulations and production requirements. Whether it's high-speed production lines or specialized formulations, our dies deliver consistent performance and reliability in diverse manufacturing environments.

Unique Selling Points:

- Exceptional Durability: Our carbide inserted dies are built to withstand the most demanding production environments, ensuring long-lasting performance and reliability even under high-pressure conditions.

- Precision Performance: With unmatched dimensional accuracy and geometric precision, our dies guarantee uniform tablet quality and optimal production efficiency, making them the preferred choice for pharmaceutical manufacturers worldwide.

- Tailored Solutions: We collaborate closely with our customers to provide customized solutions that address their specific tablet compression needs, offering comprehensive support and expertise throughout the manufacturing process.

Invest in the reliability and performance of our carbide inserted dies, and experience the difference they can make in optimizing your tablet compression operations. Contact us today to learn more about our innovative solutions and how they can benefit your pharmaceutical manufacturing processes.